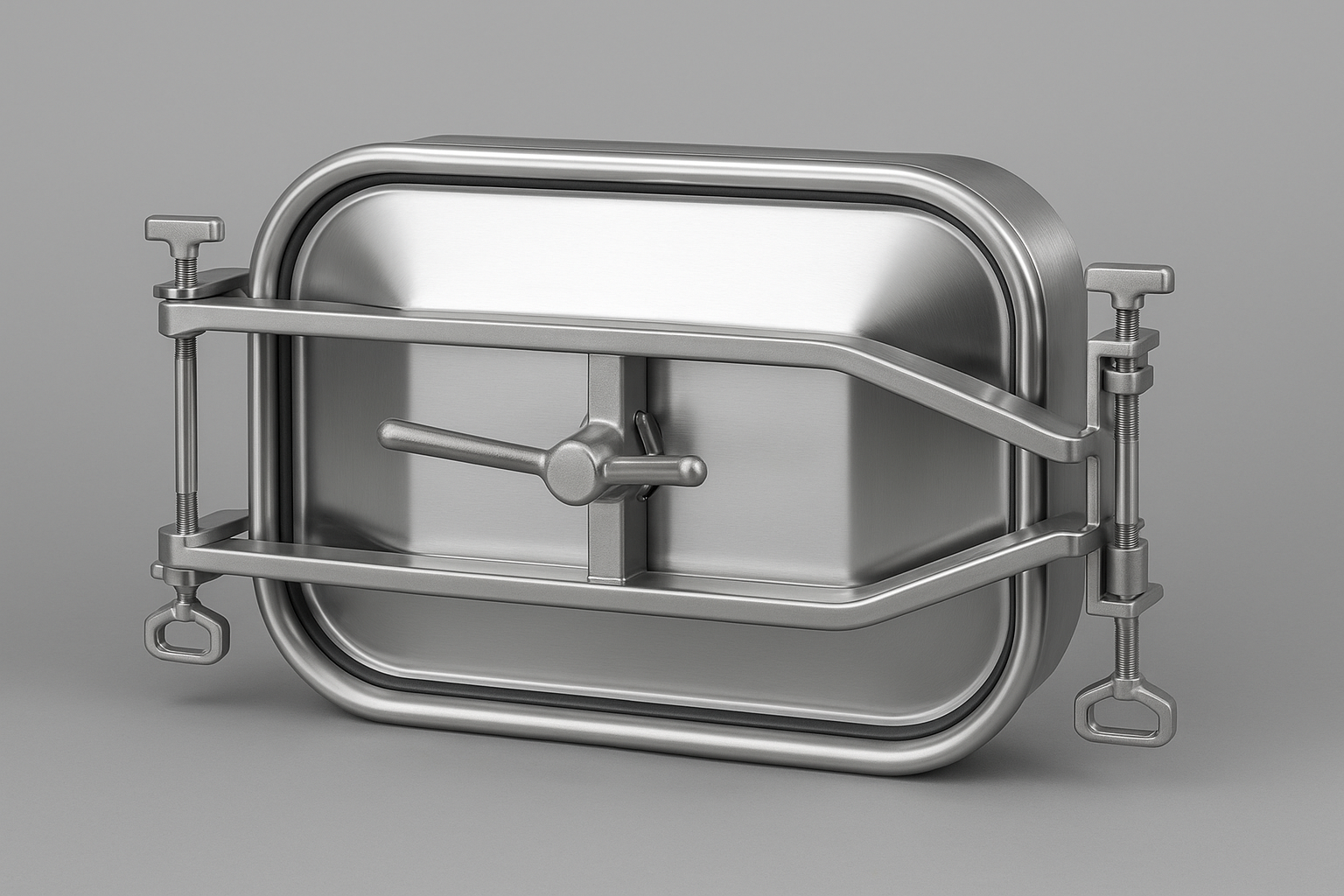

Manways installed in industrial tanks play a bigger role than most people realize. They give you access to the inside of the vessel, simplify inspections, speed up cleaning and keep entire processes safe and predictable. Among the different shapes, rectangular manways stand out because they offer a wide opening and comfortable access even in narrow production rooms. Before you choose a model for your system, it’s worth understanding where each type works best and what features actually matter in daily use.

Why rectangular manways are used in modern processing plants

When you look at the layout of food, chemical or pharmaceutical installations, one thing becomes obvious — space is always limited, and workers need a quick way to enter a tank. This is where tank manways offer a practical advantage. The rectangular shape gives technicians more room to work during inspections or repairs, and the wide opening allows tools, hoses or cleaning equipment to be placed inside without unnecessary effort.

Stainless-steel construction plays a crucial role here. It resists corrosion, handles aggressive cleaning agents and maintains structural strength even after years of intensive use. This makes rectangular manways a reliable choice for tanks operating under demanding hygienic requirements.

Another benefit is the flat profile of the frame. Because the edges do not protrude like in some circular models, tanks can stand closer to walls or machinery. Plants with tight spaces appreciate this, as every extra centimeter can simplify installation and future maintenance.

Key features to consider before selecting a rectangular manway

Even if two manways look similar at first glance, their specifications make a huge difference in practice. Several elements determine how the hatch behaves under pressure, how durable the seal is and how easy the opening mechanism works.

Here are the aspects you should always check:

- Material grade – AISI 304 works well for standard applications, while AISI 316L offers improved resistance to chemicals and chloride-rich environments.

- Opening direction – inward-opening manways allow safe operation under higher internal pressure, while outward-opening models offer faster access for cleaning.

- Gasket type – EPDM, silicone or NBR each handle different temperatures and chemicals. Choosing the right seal prevents leaks and reduces the frequency of replacements.

- Frame height and thickness – both influence durability, stability and long-term performance, especially for tanks cleaned with high-pressure systems.

- Locking mechanism – simple swing bolts are enough for low-pressure tanks, while reinforced clamps or multi-point locking systems are better for aggressive processes.

Manufacturers usually provide detailed drawings and pressure ratings. Reviewing these specifications upfront prevents costly mismatches between a tank and the selected manway.

Where rectangular manways work best in everyday operations

These hatches are particularly popular in industries where frequent internal access is necessary. Regular inspections, CIP procedures or manual cleaning become easier when workers do not need to squeeze through restricted openings.

Most commonly, rectangular manways are installed in:

- dairy tanks for milk and whey processing,

- brewery vessels, fermenters and mash tuns,

- wine and juice storage tanks,

- cosmetic and hygiene-product mixers,

- chemical tanks where visual inspection is required more often.

A rectangular opening improves ergonomics. Technicians can enter safely, maintain proper body posture and work faster, which directly reduces downtime. For installations running around the clock, minimizing downtime is one of the simplest ways to protect production efficiency.

Why stainless-steel rectangular manways improve long-term maintenance

Maintenance teams often point out that a well-designed manway can save countless hours annually. Easy access means less time spent preparing for cleaning or inspecting the vessel. But materials and construction matter just as much.

Stainless steel provides natural resistance to corrosion, which is critical in environments full of moisture and cleaning chemicals. It also ensures that the frame keeps its shape over time, which protects the integrity of the sealing system. A deformed or worn frame is one of the main causes of leaks — choosing a solid model eliminates this problem from the start.

Another strength is the smooth internal surface. Polished stainless steel minimizes residue buildup and makes cleaning quicker. This also supports hygienic standards, helping facilities comply with food-safety or pharmaceutical regulations without requiring extensive manual cleaning.

How to match a manway to your tank and working conditions

Before ordering a rectangular manway, it’s worth collecting several essential details about your installation. This avoids issues during assembly and ensures that the hatch performs as expected.

The most important factors include:

- tank pressure and operating temperature,

- product type stored inside (food, chemicals, cosmetics),

- cleaning method (manual, CIP, high-pressure systems),

- installation space available around the tank,

- frequency of maintenance and inspections,

- hygienic standards required for your industry.

With this information, it becomes easier to choose the right combination of material, seal type, opening direction and locking mechanism. In many cases, the most reliable approach is to consult technical documentation or speak directly with a supplier experienced in rectangular stainless-steel manways.